Services

SpecTape of Wisconsin

offers additional services

SpecTape of Wisconsin offers you a number of helpful services to ensure we deliver the exact product you need for your application. With less material waste and production-ready shapes, lengths and widths, you can speed up your production time and save money in the process. Our strict quality assurance procedures ensure the processes and lot numbers for each product is traceable. As your single source provider, we are willing to stock product, fulfill blanket orders, fulfill Rush Orders and offer you JIT delivery. With hundreds of items in-stock we offer you high product availability.

Our converting operation is in Erlanger, KY

Custom Printing

Bar Coding

Precision Die Cutting

In most cases custom die cutting is available on both pressure sensitive and non-pressure sensitive materials to meet the exacting requirements of your application. Tight tolerance includes pieces, pads, rolls or sheets.

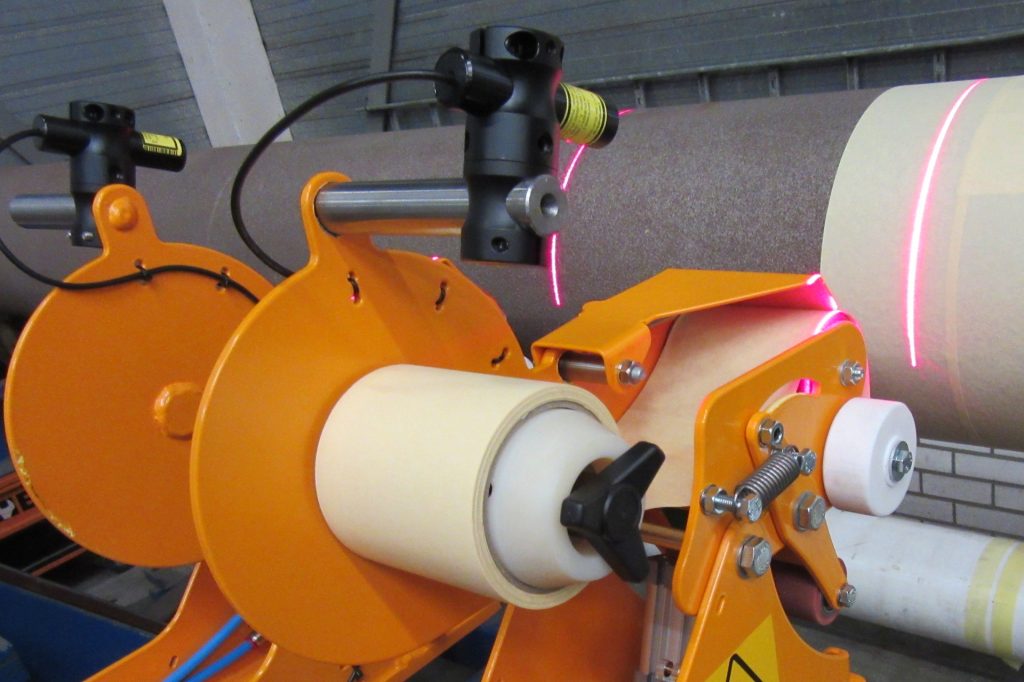

• Rotary die Cutting

• Flatbed die cutting

• Sheeting

• Square or butt/cut in roll form or cut pieces

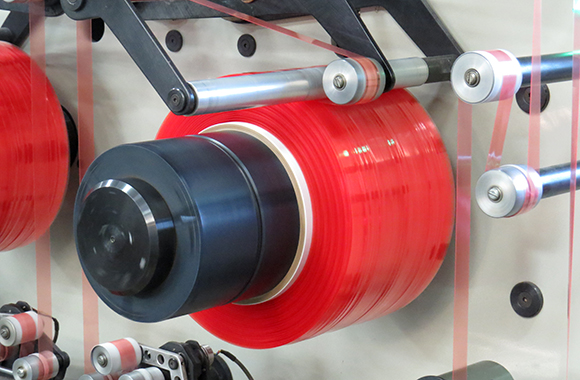

Slitting and Rewinding

Spooling

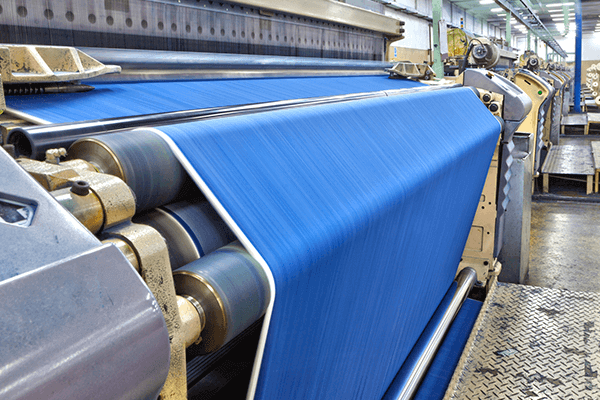

Adhesive Coating

Laminating

Application Engineering

Working with your team of professionals, we will evaluate the exacting requirements of your particular application and recommend the specific product and processes you need to save money, increase production output, improve production time, and reduce production downtime. With over thirty-five years experience in the industry, SpecTape of Wisconsin will ensure you get exactly what you need.